- News and events

- News

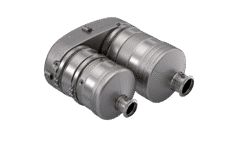

- 2023.11, Fuel Cell Exhaust Systems

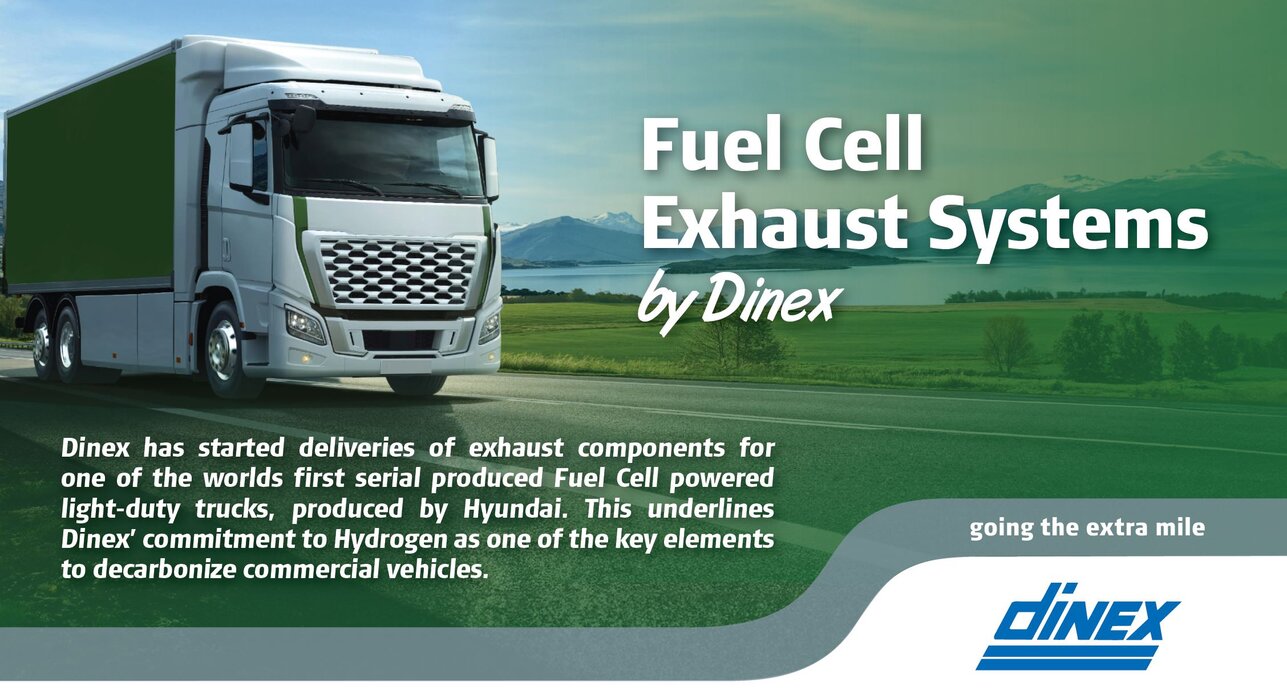

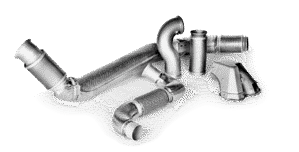

The only “tailpipe” emissions from a vehicle powered by a Hydrogen Fuel Cell are water vapor. But even such a relatively harmless compound calls for a cleverly designed exhaust solution that can…

- Properly discharge all water and condensation from the system.

- Reduce the typically high-pitch noises generated by the turbine.

- Allow for as little back-pressure as possible.

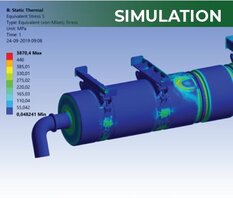

The inside of a fuel cell exhaust system is exposed to a highly corrosive environment, and failure to design the proper solution may leave customers with a system of low performance and durability. This is where Dinex’ expertise from over 40 years of designing exhaust systems for commercial vehicles comes into play: Not only material selection is critical, but also the right flow design in order to avoid gatherings of condensed water, and damages or partial flow blockages due to freezing ambient temperatures.

Dinex’ solution for Hyundai’s Fuel Cell powered truck fully meets all engineering specifications, and our team is looking forward to continued collaboration and similar projects

Dinex in the Hydrogen Economy

Dinex is active on multiple fronts to support the rise of Hydrogen in on-road transportation, and are engaged in multiple application development projects for OEM customers within:

- Hydrogen Fuel Cell Exhausts and Pipe Technology Systems, including insulation and leak-tight decoupling.

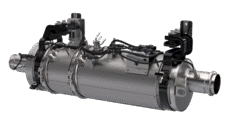

- Emission AfterTreatment Solutions for Hydrogen Combustion Engines (H2-ICE)

- Catalyst Coated Membranes (CCMs) for Hydrogen Fuel Cells

At the IAA and Bauma fairs in 2022, Dinex was the only exhibitor to demonstrate a full exhaust solution for Hydrogen Combustion Engines (H2-ICE), developed in joint partnership with a long-standing OEM customer. It is based on an SCRcatalyst which our researchers have customized for the specific chemical characteristics of combusted Hydrogen emissions.

Combined with our innovative NOX storage catalyst that captures and withholds NOX-emissions during unfavourable temperature conditions, and the option of adding our High-Porous Silicon Carbide for trapping of particles down to 10 nm, H2-ICEs has the potential of being nearly every bit as near-zero tailpipe emission as a Fuel Cell.

Meanwhile, the research staff in our recently established lab in Bayreuth is working on a new generation of Catalyst Coated Membranes – the key element of a Fuel Cell – engineered specifically for the performance requirements of heavy-duty applications and is eager to present the first prototype in 2024.

Jerry Song

Vice General Manager, Dinex China

yso@dinex.cn

Evangelos Georgiadis

Group CTO, Development

evg@dinex.de

Hans-Joerg Rembor

Fuel Cell Business Manager

hjr@dinex.de

A glimpse of the Dinex OEM Division

Global Footprint - Local Presence

Operating with local teams close to our customers, backed up by global technical competences.

Core Technologies - Proven Solutions

All developed and produced in-house for a simple, cost efficient supply chain with highest solution ownership.

Ceramic and Metallic

Substrates with catalytic coating

Pipes, Zero-Leakage Decoupling

and Thermal Management

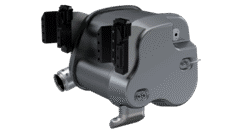

Canning and system integration

with optimal flow and mixing

Agile Partnership - Customized Innovations

Full System and customer specific engineering approach: From final application down to coating formula.

In-line system

Box system

U-Shape system