- News and events

- News 2024

- 2024.08, Key to Extending the Life of Your Sensors

Understanding the Role of Sensors in Heavy-Duty Engines

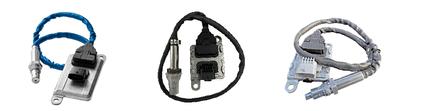

NOx Sensors: These sensors measure the levels of nitrogen oxides in the exhaust system, which are pollutants regulated by environmental standards. Accurate NOx readings are essential for maintaining compliance and optimizing the exhaust aftertreatment process.

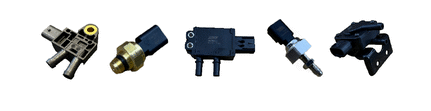

Pressure Sensors: These sensors monitor various pressure levels within the engine, including fuel pressure, oil pressure, and air pressure. Maintaining proper pressure levels is vital for engine efficiency. If a sensor detects the pressure is out of spec it will alert the ECM to prevent progressive damage.

Temperature Sensors: These sensors track the engine’s temperature to alert the ECM if temperatures are not in range. They play a crucial role in managing engine performance and preventing thermal damage.

The Impact of Engine Maintenance on Sensor Longevity

Preventing Contamination

Regular engine maintenance, such as changing air and fuel filters, helps prevent contaminants from entering the engine. Dirt, debris, water, and poor combustion leading to excessive carbon in the exhaust can lead to inaccurate readings and potential sensor failure. Clean filters ensure that the sensors receive unpolluted air and fuel, enhancing their accuracy and longevity.

Ensuring Optimal Combustion

Proper maintenance of the fuel injection system ensures that the engine receives the correct fuel-to-air ratio, which is essential for efficient combustion. An optimized combustion process reduces the production of soot and other particulates that can damage NOx sensors and other exhaust components. On time replacement of fuel filters and using high-quality fuel can significantly improve sensor performance.

Reducing Thermal Stress

Maintaining the cooling system is crucial for managing engine temperature. Overheating can cause thermal stress on temperature sensors and other engine components, leading to premature failure. Coolant levels should be checked daily and low coolant should be investigated promptly. Periodic inspection of the radiator to ensure proper airflow can prevent overheating and extend the life of temperature sensors.

Maintaining Proper Pressure Levels

Pressure sensors rely on accurate readings to function correctly. Regular maintenance of the oil and fuel systems, including checking for leaks and ensuring proper lubrication, helps maintain stable pressure levels. This not only protects the sensors but also ensures the engine operates efficiently.

Avoiding Soot and Particulate Buildup

The EGR (Exhaust Gas Recirculation) system recirculates a portion of the exhaust gases back into the engine to reduce NOx emissions. However, if the EGR system is not properly maintained, it can lead to soot and particulate buildup, which can damage NOx sensors and other components. Regular cleaning and inspection of the EGR system can prevent such issues and prolong sensor life.

Best Practices for Engine Maintenance

• Regularly Replace Filters: Air, fuel, and oil filters should be replaced according to the manufacturer’s recommendations to keep contaminants out of the engine. High idle applications should use engine hours as opposed to miles for service intervals.

• Monitor Fuel and Oil Quality: Use high-quality fuel and oil to ensure optimal engine performance and protect sensors from damage.

• Inspect Cooling Systems: Regularly check and maintain the cooling system to prevent overheating and thermal stress on sensors.

• Service the EGR System: Clean and inspect the EGR system to prevent soot buildup and ensure it functions correctly.

• Check for Leaks: Regularly inspect the engine for any leaks that could affect pressure levels and overall performance

Conclusion

The longevity and performance of NOx, pressure, and temperature sensors in heavy-duty semi-truck engines are directly influenced by the quality of engine maintenance. By taking proactive steps to maintain the air intake system, fuel system, cooling system, and the EGR system, you can prevent sensor failure, enhance engine efficiency, and avoid costly repairs. Investing in regular engine maintenance not only keeps your sensors functioning optimally but also ensures that your semi-trucks remain reliable and efficient on the road.

Trust in Dinex - Your One-Stop-Shop

At Dinex, we’re your one-stop shop for all your heavy-duty vehicle needs - sensors included. Whether it’s NOx sensors, temperature sensors, or pressure sensors, our products are designed for durability and precision. Trust Dinex to provide the high-quality components you need to keep your engine running smoothly and efficiently, ensuring long-lasting performance and reliability on the road.