- News and events

- News 2024

- 2024.10, Benefits of Keeping Clean DEF Systems

Why DEF Systems Matter

DEF systems are designed to reduce nitrogen oxide (NOx) emissions by converting them into harmless nitrogen and water vapor through a process called selective catalytic reduction (SCR). This system is essential for helping vehicles meet EPA emissions standards while improving fuel efficiency. However, if a DEF system is not properly maintained, it can lead to costly breakdowns, increased emissions, and poor overall performance.

Clean DEF systems require properly functioning pumps, filters, and injectors. Without these components working efficiently, fleets risk facing frequent downtime and expensive repairs.

The Role of DEF Pumps, Injectors, and Filters

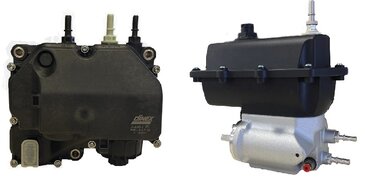

DEF Pumps: The pump is the heart of the DEF system, responsible for delivering DEF from the tank to the injector. A faulty or inefficient pump can result in inadequate DEF supply, which negatively impacts the SCR system’s ability to convert NOx.

DEF Filters: DEF filters are crucial for preventing contaminants from entering the system. Clean DEF is essential for the SCR process to function correctly. A clogged or dirty filter can cause blockages in the system, leading to reduced efficiency and potential vehicle downtime.

DEF Injectors: The injector ensures that DEF is sprayed evenly into the exhaust stream for maximum NOx conversion. A malfunctioning injector can lead to incomplete DEF injection reducing the effectiveness of NOx reduction in the SCR. It can also lead to too much DEF being injected causing DEF buildup in the decomposition tube or mixing chamber.

Maximizing Uptime and Performance: The Dinex Difference

At Dinex, we understand that fleet operators need reliable, durable, and high-performing components to keep their vehicles running efficiently. Our DEF pumps, filters, and injectors are designed to deliver exactly that.

Dinex DEF pumps are built for durability and precision, our DEF pumps are engineered to deliver consistent flow rates, ensuring optimal DEF injection. This not only helps maintain emissions compliance but also improves fuel efficiency.

Dinex DEF filters are designed to block contaminants while maintaining a smooth DEF flow - comparable to OE. This extends the life of your SCR system and prevents costly repairs due to clogs or system failures.

Dinex DEF injectors are focused on accuracy and provide consistent and precise DEF injection, ensuring that your vehicle stays within NOx emission limits while maximizing performance.

The Benefits of Keeping Your DEF System Clean

Investing in high-quality DEF components from Dinex offers several key benefits for fleet operators:

• Increased Efficiency: Clean and properly functioning DEF systems optimize the SCR process, leading to better fuel efficiency and lower overall operational costs.

• Reduced Downtime: High-quality DEF components reduce the risk of system failures, meaning fewer breakdowns and less time off the road for your fleet.

• Extended System Lifespan: Proper maintenance and reliable components can extend the lifespan of your DEF system, protecting your investment and ensuring long-term reliability.

• Compliance with Emission Standards: Staying compliant with emissions regulations is critical for avoiding fines and ensuring your fleet operates legally. Dinex components help ensure that your vehicles meet or exceed these standards.

The Bottom Line

Regular DEF filter maintenance is essential for fleet operators looking to minimize downtime, prevent costly repairs, and ensure compliance with emissions standards. A well-maintained DEF system, supported by high-quality filters, helps keep your trucks on the road longer, reducing overall operational costs and improving efficiency. By proactively addressing potential issues with the right components, fleet managers can avoid the headaches and financial strain caused by neglected DEF systems.

Trust in Dinex - Your One-Stop-Shop

When it comes to maximizing your fleet’s uptime, Dinex is your one-stop shop for all your exhaust aftertreatment needs. From turbo to tailpipe, we’ve got you covered with durable, high-efficiency DEF pumps, filters, and injectors that protect your entire SCR system, ensuring smooth operation and long-lasting reliability. Our comprehensive range of products is designed to reduce maintenance time and costs while extending the life of your aftertreatment system. Keep your fleet performing at its peak—trust Dinex for top-tier aftertreatment system protection and performance, including complete DEF system solutions.